https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling Systems

https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling SystemsWhy Should You Have a Robotic Tote Handling System?

What if you could transform your warehouse operations to be more efficient, accurate, and productive without the constant worry of human error? Robotic tote handling systems offer sophisticated technology to optimize your warehouse workflow. Don’t let outdated processes hold your warehouse back.

What Is a Robotic Tote Handling System?

Robotic tote handling systems streamline operations and propel efficiency. These automated systems consist of robotic units specifically engineered to transport totes. Their primary function is to ensure that products are moved smoothly and swiftly across various processing points.

Robotic tote handlers are adept at picking, placing, and transferring totes to designated areas without human intervention, minimizing the risk of human error. They fit seamlessly into an existing warehouse infrastructure, often complementing other automated systems. From organizing inventory to preparing orders for shipment, these robots help facilitate day-to-day operations.

Featuring advanced sensors and intelligent software, robotic tote handling systems can navigate complex warehouse environments. They intelligently adapt to changes in workflow and can operate around the clock, drastically increasing a warehouse’s potential for continuous and productive operation.

Increased Productivity and Efficiency With Robotic Assistance

Robotic tote handling systems, like the AirRob, optimize product storage and retrieval. Their sophisticated algorithms enable them to mitigate bottlenecks by sorting and placing goods in an orderly and strategic fashion, facilitating faster access when the time comes for retrieval. This streamlined process accelerates the pace of warehouse storage activities and increases the overall throughput.

Robotic Tote Handlers Maintain Consistent Workflow

Robotic tote handlers operate with precision and steadiness unrivaled by human operators. These robots ensure a continuous, predictable flow of operations by minimizing delays and reducing the potential for bottlenecks. This creates a stable environment where productivity levels are upheld, leading to higher output and greater efficiency.

Here’s how tote systems help improve your workflow:

- Minimization of Delays: Robots are unaffected by fatigue, leading to a substantial decrease in downtime.

- Predictable Scheduling: Automated systems can work around the clock without the need for breaks or shift changes.

- Enhanced Throughput: With faster retrieval times and the ability to handle multiple tasks simultaneously, robotic tote handlers boost overall throughput.

Enhanced Accuracy and Reduced Errors

Robotic tote handling systems follow precise instructions without deviation, drastically improving item-picking accuracy. This sophistication ensures that the right item is selected every time, effectively minimizing the risk of human errors due to fatigue or simple oversight.

The Precision of Robotic Systems in Handling Inventory

Robots have various sensors and tools to handle inventory with exceptional precision. Unlike manual handling, where items can be placed erroneously or mishandled, robotic systems ensure that every item is placed accurately in its designated location, reducing the risk of inventory mismanagement and the associated costs of rectifying such errors.

Error Tracking and Resolution

When errors do occur, robotic systems are equipped with diagnostic tools that facilitate quick identification and the necessary corrections. Swift resolution minimizes downtime and enhances the overall reliability of warehouse operations.

Don’t let outdated processes hold your warehouse back. Upgrade to the innovative AirRob tote handling system and witness improved efficiency, precision, and productivity in your operations.

Why You Should Consider the AirRob Tote System

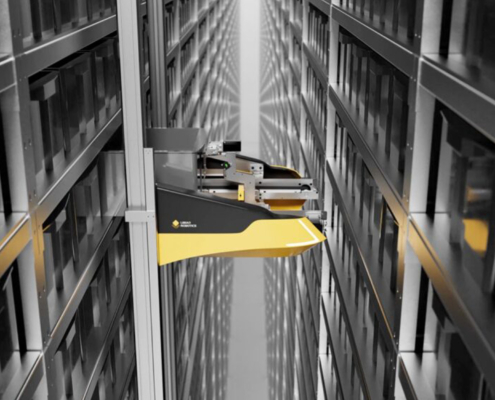

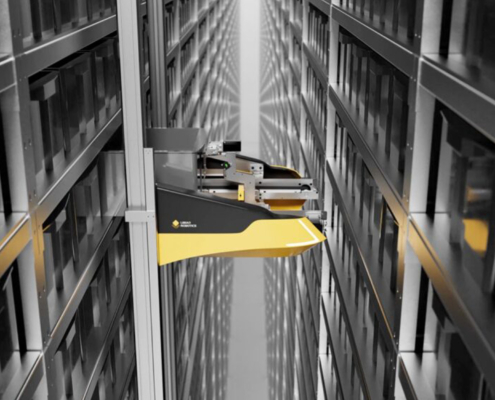

The demands of modern e-fulfillment and warehouse operations require solutions that elevate efficiency and productivity to new heights. The AirRob tote handling system delivers unmatched performance and functionality for the needs of the modern warehouse.

AirRob is an energy-efficient solution that offers unprecedented storage density, ensuring rapid and accurate picking. This system has the agility and precision needed to future-proof warehouse operations and accommodate business growth.

Some of the stand-out qualities of the AirRob include:

- Installation of the AirRob system is simple and cost-effective, integrating seamlessly into existing warehouse infrastructures without the need for extensive renovations or downtime.

- The system operates on a lightweight frame attached directly to storage racking and can reach impressive speeds of up to 2 meters per second horizontally and vertically. This facilitates quick and fluid movement throughout the facility.

- With the capability to handle loads of up to 30kg, AirRob expertly navigates to the desired location within the storage system to automatically pick totes and efficiently deliver them to ground level.

- A specialized transfer robot assumes the role of a mobile pick-and-drop station, taking the tote box to a designated workstation. There, an operator can easily access and process the items before the tote is returned to the racks by the same diligent transfer robot.

Polymatic Is Your Source for High-Quality Tote Handling Systems

Polymatic is proud to offer the AirRob tote handling system in partnership with Libiao Robotics. With cost-effectiveness, scalability, and robust performance, the AirRob system enhances how mobile robots integrate into your workflows. Whether you’re looking to improve throughput, minimize operational costs, or both, the AirRob system is an automation solution crafted to meet the dynamic demands of modern warehousing.

Ready to optimize your tote-handling processes? Reach out today.

Share This Post

More Like This

https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling Systems

https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling Systems https://polymaticsolutions.com/wp-content/uploads/2024/10/Scalability-and-Flexibility-in-the-AirRob-Robotic-Tote-Handling-System.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 10:59:482025-07-09 13:31:35Scalability and Flexibility in the AirRob Robotic Tote Handling System

https://polymaticsolutions.com/wp-content/uploads/2024/10/Scalability-and-Flexibility-in-the-AirRob-Robotic-Tote-Handling-System.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 10:59:482025-07-09 13:31:35Scalability and Flexibility in the AirRob Robotic Tote Handling SystemLocation

Get In Touch

Phone

(909) 644-7479

Services

About Us

At Polymatic, your design is our mission. We learn your short and long-term goals and provide stellar warehouse solutions that refine and reinforce your supply chain.