https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling Systems

https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling SystemsScalability and Flexibility in the AirRob Robotic Tote Handling System

Upgrade your warehouse operations with the AirRob system—a scalable, flexible solution that exceeds the demands of modern logistics.

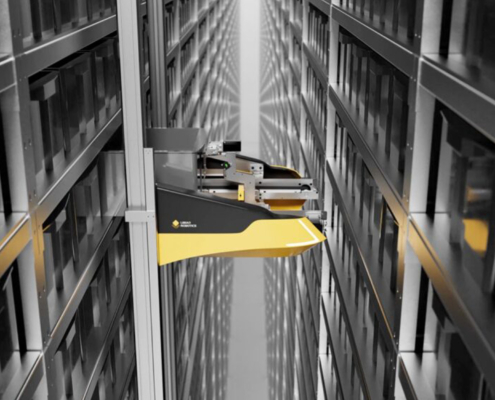

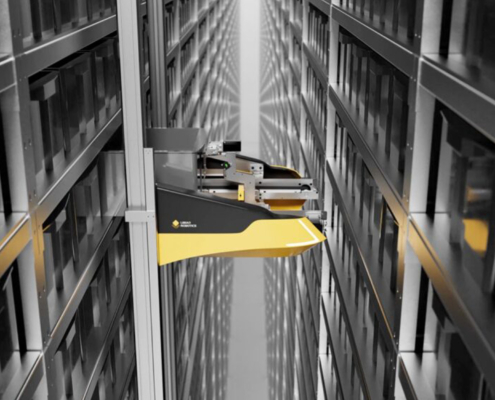

What Is the AirRob Robotic Tote Handling System?

The AirRob robotic tote handling system provides an efficient, scalable, and flexible solution for warehousing and distribution workflows.

The AirRob system is a blend of cutting-edge technologies that enhance speed and reliability. It includes automated robots, intelligent software for real-time operation management, and advanced sensors that enable precise tote handling. This integration results in a system that optimizes space, minimizes errors, and adapts to many tote sizes and shapes.

Meeting Scalability in Warehouse Operations

Whether you’re dealing with a seasonal surge, a promotion-induced spike in orders, or long-term growth, your warehouse can maintain pace thanks to the adaptable nature of the AirRob tote handling system. No more bottlenecks during peak periods—just a smooth, continuous flow of goods that meets your throughput requirements daily.

Multi-AirRob Deployment for Enhanced Throughput

The AirRob system is designed for scalability. Multiple AirRob units can operate on a single aisle, ensuring a continuous and efficient workflow. As your business grows, the system scales effortlessly by integrating additional racks. This results in increased throughput without compromising on space or efficiency.

Twin Directional Picking

The AirRob’s twin directional picking capability services racks both in front and back. This unique feature maximizes the efficiency of your picking process and significantly increases the number of orders that can be processed within the same footprint.

Maximizing Warehouse Space With Innovative Design

Every square meter in a warehouse is valuable real estate. The AirRob system helps your operation thrive even in limited spaces. By supporting an aisle width as narrow as 0.85m, the AirRob facilitates the creation of more rack space to accommodate growing inventory levels without the need for costly expansions.

Creating More Tote Storage With Precision Handling

The AirRob robotic tote handling system maintains a gap between totes of only 10 to 30mm, which ensures that every available inch is used effectively. This precision creates space for more totes, maximizing storage density—vital for high-volume operations aiming to scale swiftly and successfully.

Take your warehouse efficiency to the next level with the AirRob system. The Polymatic team is ready to help you implement a scalable, flexible solution tailored to your needs.

Flexibility in Warehouse Solutions and the AirRob Advantage

The need for flexible and innovative solutions in warehouse operations has never been greater. The AirRob Robotic Tote Handling System provides unparalleled flexibility tailored to modern warehouse needs.

Unrestricted Tote Transfer With AirRob

The AirRob system seamlessly integrates with existing floor robots, transferring totes to floor-based robots at any location beneath the racking system. This adaptability enables the system to fit into various warehouse layouts and work with other robotic systems, minimizing downtime and boosting overall productivity.

High-Volume Handling for Flexible Applications

The AirRob System can process over 20,000 totes per hour, making it ideal for high-volume operations. It is flexible enough to handle peak times, adaptable to various tote sizes and types, and suitable for many industries. This robust throughput ensures that your warehouse can meet increasing demands efficiently and effectively.

How the System Fits into the Current Warehousing and Distribution Landscape

The AirRob system meets the dynamic needs of modern warehouse operations. From small start-ups to extensive distribution networks, the system offers unmatched versatility in its implementation. Whether it’s increasing throughput, handling peak season demands, or reducing reliance on manual labor, AirRob is a worthwhile investment.

Here are the biggest ways the AirRobe handling system helps warehouses:

- Improving process efficiency with smart automation.

- Providing scalable solutions to grow with your business needs.

- Ensuring a flexible approach to cater to various operational demands.

- Reducing the physical strain on warehouse staff and enhancing safety.

Optimize Your Warehouse Operations With Polymatic and the AirRob System

Polymatic is excited to partner with Libiao Robotics to bring you the AirRob robotic tote handling system. As consultants, we design innovative and efficient solutions tailored to your needs. The AirRob system is state-of-the-art and cost-effective, offering high storage density and rapid flow rates to keep up with current and future demands. With its versatility and compatibility, AirRob easily integrates with your existing infrastructure, minimizing transition costs and complexity.

Ready for a comprehensive approach to optimizing your warehouse operations? Reach out today.

Share This Post

More Like This

https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling Systems

https://polymaticsolutions.com/wp-content/uploads/2024/10/Comparing-AirRob-Robots-to-Traditional-Tote-Handling-Systems.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 11:00:502025-07-09 13:31:35Comparing AirRob Robots to Traditional Tote Handling Systems https://polymaticsolutions.com/wp-content/uploads/2024/10/Why-Should-You-Have-a-Robotic-Tote-Handling-System-scaled.jpg

958

2560

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 10:21:342025-07-09 13:31:35Why Should You Have a Robotic Tote Handling System?

https://polymaticsolutions.com/wp-content/uploads/2024/10/Why-Should-You-Have-a-Robotic-Tote-Handling-System-scaled.jpg

958

2560

Abstrakt Marketing

/wp-content/uploads/2022/10/Polymatic-Solutions-Logo-Color.svg

Abstrakt Marketing2024-10-21 10:21:342025-07-09 13:31:35Why Should You Have a Robotic Tote Handling System?Location

Get In Touch

Phone

(909) 644-7479

Services

About Us

At Polymatic, your design is our mission. We learn your short and long-term goals and provide stellar warehouse solutions that refine and reinforce your supply chain.